In the field of after-sales service for mechanical equipment, the traditional "repair request - response - dispatch - on-site repair" model is facing unprecedented challenges: long customer waiting times, high service costs, and exhausted engineers. With the deepening of digital transformation, an innovative service model is emerging — through interactive 3D animation technology, transforming passive response after-sales into a customer self-service mode, achieving a win-win situation.

Building an Immersive Self-Service Platform: From "Relying on Engineers" to "Self-Control"

Interactive 3D animation, through highly simulated equipment models and intelligent interactive design, enables customers to independently explore equipment structures, understand operating principles, and master maintenance essentials. This immersive experience greatly enhances the customer's ability to solve problems independently.

Taking Shenzhen Wande Digital Technology Co., Ltd. as an example, the company has developed an interactive 3D animation system for its digital printing presses that supports multi-touch and free viewpoint switching. Customers can freely zoom in, rotate the equipment model, and observe internal structures from any angle via tablet devices. This innovation has enabled customers to independently resolve over 70% of common faults, reducing service response time from hours to instant, achieving true "zero waiting" service.

Precise Guided Maintenance: From "Blind Attempts" to "Accurate Operation"

In traditional maintenance, customer misoperations due to a lack of understanding of equipment structure are common. Interactive 3D animation ensures customers perform operations accurately at each step through step-by-step guidance and intelligent prompts.

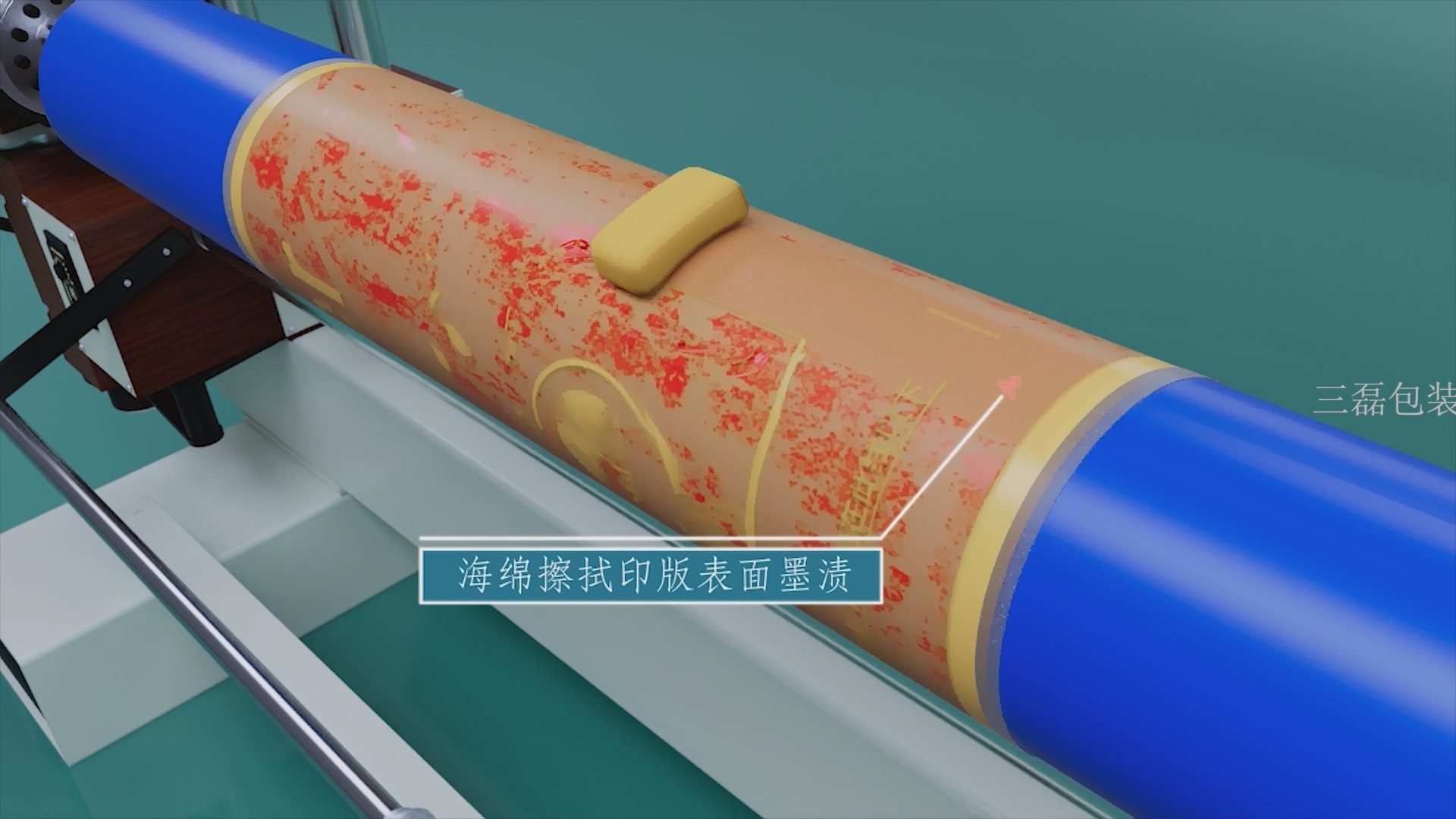

The interactive animation for flexographic printing presses by Xiamen Sanlei Packaging Materials Co., Ltd. breaks down complex operations such as plate roller replacement and printing pressure adjustment into clear step-by-step processes. The system automatically identifies the customer's current operational step and provides corresponding visual prompts and precautions. This precise guidance has increased the first-time operation accuracy rate to over 90%, significantly reducing the risk of secondary damage caused by misoperations.

Multi-dimensional Training Empowerment: From "Single Guidance" to "Comprehensive Mastery"

Interactive 3D animation not only solves immediate problems but also focuses on enhancing customers' long-term operation and maintenance capabilities. Through functions like simulated operations, fault re-enactment, and assessment, the system provides customers with comprehensive technical training.

The multilingual interactive training system developed by Foshan Jinbing Machinery Co., Ltd. supports customers in repeatedly practicing operations such as equipment disassembly, assembly, and maintenance in a virtual environment. The system records operational trajectories in real-time and provides scores, helping customers identify skill gaps. This training method has reduced the onboarding training period for new employees by 50%, effectively addressing the challenge of professional talent shortages.

Data-Driven Service Optimization: From "Experiential Judgment" to "Precise Improvement"

The backend of the interactive 3D animation system can collect customer usage data, analyze frequently accessed content, operational difficulties, and knowledge gaps, providing data support for service optimization.

When system data analysis shows that specific fault diagnosis modules for a certain equipment model are frequently accessed, engineers can improve the design of that part accordingly. This data-driven optimization mechanism not only enhances after-sales service quality but also provides precise direction for product iteration, achieving a reduction in failure rates from the source.

Building a Win-Win Ecosystem: From "Cost Center" to "Value Co-creation"

When customers can solve problems independently through interactive 3D animation, the service team is freed from repetitive tasks, focusing on more valuable technical research and development and complex issue resolution. Meanwhile, companies can develop more value-added services based on platform data and explore new revenue streams.

After implementing interactive 3D animation self-service, Ruichang Carton Machinery Manufacturing Co., Ltd.'s service engineers can dedicate more energy to equipment optimization and process improvement. This shift not only enhances customer production efficiency but also generates additional technical service revenue for the company, achieving true value co-creation.

Interactive 3D animation is reshaping the essence of after-sales service for mechanical equipment. By building intuitive and easy-to-understand visual guidance systems, precise operational guidance mechanisms, multi-dimensional training systems, and data-driven optimization loops, it successfully transforms after-sales service from a passive "firefighting" response to an active customer self-service mode. This transformation not only brings a qualitative leap in service efficiency but also redefines the relationship between manufacturers and customers—upgrading from simple service providers and receivers to value-creating partners for mutual growth. In today's era of digital wave sweeping through manufacturing, investing in an interactive 3D animation self-service platform is no longer just a technological innovation but a strategic choice for the future.

Selected FAQs:

Q: What categories does Xuncheng animation video production include?

A: Animation video production includes the following three categories:

Promotional: Including product promotion, corporate promotion, etc.

Technical: Including equipment operation, equipment maintenance, equipment repair, wearing parts replacement, equipment assembly, equipment safety, etc.

Customized: Including exhibition videos, investment promotion videos, event warm-up videos, etc.

Q: What are the benefits of equipment operation and maintenance animation for machinery factories?

A: Benefits of demonstrating equipment operation and maintenance through animation:

1- Provides customers with more professional after-sales support. Operation animations can quickly train new staff; maintenance animations ensure standardized upkeep, keeping equipment in peak condition; repair animations allow customers to self-resolve common minor faults, effectively improving equipment uptime; wearing parts replacement allows customers to flexibly schedule replacements based on production needs; assembly animations can significantly reduce reliance on experienced installation personnel; safety animations provide professional safety guidance and training materials for customers.

2- Effectively enhances customer stickiness. Practice shows that customers greatly prefer using animated demonstrations to solve various problems during equipment use, making animations highly engaging for customers.

3- Significantly reduces after-sales service pressure, especially during the warranty period (customers have reported a reduction of at least 30%-40% in unnecessary after-sales services), with the effect becoming more pronounced as the volume of shipped machines increases.

4- Becomes a powerful sales tool. Equipment manufacturers that have produced operation and maintenance animations can market a novel concept to customers: worry-free equipment usage.

5- Reduces training costs, lowers equipment repair costs, and improves production efficiency.

6- Enhances brand image and market competitiveness, facilitating technology dissemination.

Q: How to produce 3D animations related to equipment repair?

A: Most machinery and production factories rely on experienced, qualified electromechanical engineers for equipment repair. Equipment repair animations can effectively solve this problem.

1- It is recommended to start by producing repair animations for common equipment failure points (including mechanical and electrical);

2- Record and document on-site repairs to accumulate material for animation production;

3- Quantity: For large equipment, it is recommended to produce about 10-15 mechanical repair animations and 5-8 electrical repair animations initially. For medium and small equipment, about 6-8 mechanical repair animations and 3-5 electrical repair animations are recommended.

4- Equipment repair animation is a process of continuous accumulation and optimization, with a relatively long production cycle. Project management personnel should be relatively stable.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startups, overseas clients, listed companies, and foreign-invested enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services, from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented with stunning 3D animation. This not only brings a unique visual experience to clients but also deeply resonates with them.